Which Glue to Use? Terminology & Everything You Need to Know About Glue!

We think about glue all the time, but we know that you probably only think about glue when you absolutely have to (i.e., during a glue-mergency!). As a result, you might not be up to snuff on your adhesive terminology! So, we thought it’d be helpful to give you a handy glue glossary, making it that much easier when deciding which glue to use!

ADHESIVE TYPES

Hot Melt: Hot melt adhesives are solid at room temperature, but when introduced to heat they become liquid and ready for application. Each hot melt adhesive has its own temperature range which will change it from solid to liquid. After the hot melt is applied to the materials being adhered together, it will solidify again and build the bond needed for the application.

Hot melt adhesives can be used for a very wide range of applications. They are used in almost all packaging applications, most labeling applications, various converting applications, and a wide variety of product assembly applications.

Liquid: Liquid adhesives are exactly what they sound like! They are in liquid form and only solidify once they have been applied to the material(s) for the application and the water has evaporated. Some liquid adhesives are strong enough internally to hold the substrates in place before the product has set up, but the adhesive is not fully cured until the water is evaporated and the solids are all that remain.

Liquid adhesives are primarily used in laminating applications, various converting applications, and some packaging applications.

Reactive: Reactive adhesives require a chemical reaction in order to adhere two materials together. This chemical reaction is activated when two components are mixed together, or the product is exposed to heat and moisture.

Reactive adhesives are used for various product assembly applications, such as bonding metal panels together (i.e., to replace welding).

Dots: You’re probably most familiar with dots because you see them in your mailbox almost every day! Dots are pressure-sensitive blobs of adhesive that simply need to be pressed together with the material in order to activate a bond.

Dots are used for various direct mail and card affixing applications that are usually done by hand. They are also common for kitting projects.

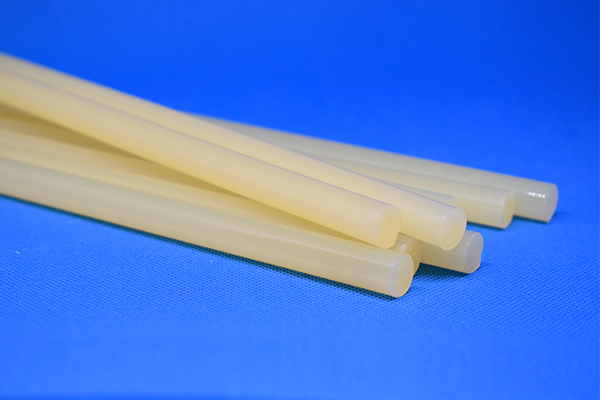

Sticks: You may already be picturing a hot glue gun in your mind – which is exactly right! Adhesive sticks are shaped like tubes and inserted into equipment in which the application onto the materials can be better controlled due to its shape.

Sticks are used for a wide variety of packaging applications done by hand, rework of failed packages from automatic lines, POP displays, and various product assembly jobs.

ADHESIVE TECHNOLOGIES

EVA: EVA stands for “Ethylene Vinyl Acetate Copolymer”. EVAs are typically light to dark amber in color and are usually brittle (though some EVAs are soft). EVAs:

– Are typically applied at 350ºF on full temps or 250ºF to 275ºF for low temps.

– Have no significant surface tack.

– Are not pressure sensitive at room temperature.

– Typically have a short open time (10 seconds or less), but various materials can be added to the formula to increase the open time.

– Have a fast speed of set.

Metallocene: Metallocenes were designed to have better pot stability and withstand the high heat from breaking down the product (on the other hand, EVAs degrade quickly). Metallocenes:

– Are typically applied at 350ºF on full temps or 250ºF to 275ºF for low temps.

– Have a faster speed of set than EVAs.

– Can almost always be dropped into any application currently using an EVA and work just fine.

– Are less dense than EVAs.

– Offer optimal strength while using less glue.

Pressure-Sensitive Adhesive (PSA): PSAs are non-reactive and form a bond when pressure is applied to the material. In addition to pressure, heat may also be needed to activate the PSA. Each pillow of adhesive has a coextruded film around the glue. This allows the product to be packaged in small pillows instead of one big block of glue. Once reheated and applied, the product is tacky to the touch. PSAs:

– Are typically applied between 350 ºF and 275 ºF.

– Have a wide range of tack. It can range anywhere from not tearing two pieces of paper stuck together to permanently adhering two substrates together.

– Will always be sticky to the touch, or at least until dust covers the tack or oil from your finger transfers from touching it too much.

– Will have a stronger bond when the substrates are put together while the product is molten.

– Have a slow speed of set.

Resin-Based: Resins are tough liquid adhesives. Resins are a great choice for automatic applications because the quicker setup time and strong wet tack may prevent any swimming of the label. They are also softer products so they can bond a wider variety of substrates. When diecutting labels, resins are better because if the product is too brittle, the blade will crack the bond. Resins:

– Dry fast.

– Have a fast set up time, meaning they can run at higher production speeds.

Dextrin-Based: Dextrins are ideal in applications with porous substrates and, like all liquid adhesives, they dry in the absence of moisture. Dextrins are soluble in water but their starch-base makes them easier to dilute and clean from machinery. Dextrins:

– Have a strong wet tack, but are less strong than resins.

– Have a medium set time.

ADHESIVE CHARACTERISTICS

Wet Tack or Hot Tack: The adhesive’s ability to hold down substrates while out of compression but still in a molten or liquid state.

Open Time: After the adhesive is applied to the material, how much time there is until the bond needs to be made. The temperature, materials, and quantity of adhesive all impact the open time. We categorize the open time as Very Fast, Fast, Medium, or Slow.

Speed of Set: When two or more materials are combined with an adhesive, how much time it takes to form a bond. We categorize the speed of set as Slow, Medium, Fast, or Very Fast.

Diameter: How wide the diameter of the dot is.

Profile: How thick the dot is.

Do you have questions about the adhesive(s) you’re using on your production line (or its properties)? Are you not sure which glue to use? Please let us know! We’d be happy to come visit your facility to audit your adhesive application and determine if there is a better adhesive for your production. Contact us today to get the conversation started!