Pivot to Pivoting Modules for Improved Productivity

Do you currently need to put down multiple beads or dots of adhesive on your piece?

Do you use multiple orifice nozzles?

Are you frequently changing those nozzles to get the correct spread and distance on your piece?

Dual orifice nozzles tend to leak or drip more than a single orifice nozzle. Those leaks and drips can mean extra unwanted adhesive in the place on your piece. Dual bead nozzles are also at a fixed angle, so to get the correct placement on your piece you could be moving your applicator head side to side or up and down. That’s lost time and performance that can be avoided.

There may be a better option for you. What if instead of dealing with the lower performance of a dual bead nozzle, you could pivot your single orifice nozzles to match the exact spot on the piece that you need?

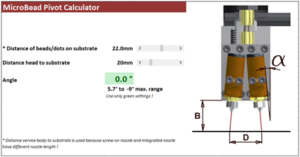

Chicago Glue and Machine supplies a MicroBead™ applicator head with dual modules that has the capability of pivoting those modules to direct a single bead of glue to the exact spot that you need. No more changing nozzles and moving your applicator. You simply adjust a few set screws and tilt the modules to your desired angle. This innovation can help reduce downtime headaches and increase uptime while improving performance compared to your current setup.

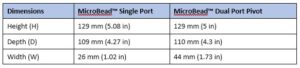

The MicroBead™ applicator is available with single-port or dual-port pivoting modules, providing flexibility for set-up and reduction of the number of applicators required. The compact design provides ease of installation and maintenance while rapid cycle speeds make it the perfect choice for high-speed applications. The air open/air close design gives accurate and uniform adhesive patterns and bead placement while the built-in filter helps keep the nozzle orifice clean.

To find out if this applicator could be a fit for your production process, contact us today.