How to Prevent Oil in Air Lines from Shutting Down Your Adhesive Equipment

You probably have oilers connected to your air lines because many machines in your plant have components that need to be lubricated. However, did you know that oil in air lines can be detrimental to your hot melt equipment?

The Problem with Oil

Piston pumps on your hot melt machines need to receive clean, dry air for maximum performance and a long operating life. When the heat from the machine reacts with the oil in the air line, the oil becomes thick, sticky “gunk” that adds stress to the pump and will affect the performance and rapidly shorten its life span.

The compressed air being sent to the solenoids on the applicator heads also needs clean, dry air and is overlooked in many cases. Any moisture or oil causes the solenoids to slow down and ultimately fail.

What You Can Do

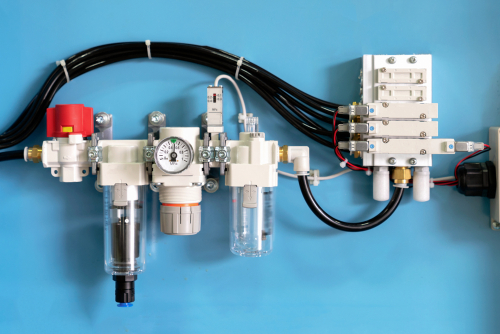

To prevent issues with your hot melt equipment, we recommend purchasing and installing filters on the air line directly before the solenoid or pump to catch all contaminants. If not captured by a filter, these contaminants may cause issues for your equipment that will shut down your lines.

For more information on preventing oil in air lines and to purchase a filter, please contact us or request a quote. Remember, CGM is available 24/7/365 to help save you from glue-mergencies!