How to Know When It’s Time to Replace your Hot Melt Hose

In the glue industry, there can be a lot of questions surrounding hot melt hoses. When should I replace them? Can’t they last forever? Why do they need to be replaced at all? No need to worry! The experts at Chicago Glue & Machine have all the answers when it comes to hot melt hoses, and in this blog we’ll dive into all the sticky details. Keep reading to learn the ins and outs of this critical adhesive application component.

Hot melt hoses do, in fact, need to be replaced. As a rule of thumb, you should prepare to replace yours every three years. Keeping this general timeline in mind makes planning for a replacement easier and will minimize downtime. When you proactively replace your hot melt hose, there is less risk for worn-down or faulty hoses to disrupt your production process.

How to tell when your hose is on the outs

There are a number of indicators that your hot melt hose is nearing the end of its lifespan. Keep an eye out for these issues:

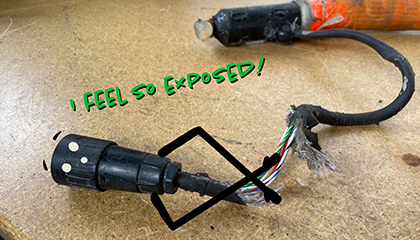

- Exposed wires

- Damage to hot melt hose wrapping

- Leaking on either end of the hose due to cross threading of fitting

- Frequently clogged nozzles

- Char coming out of the hose when the tank is cleaned

- Water damage

Any of these issues may be a signal that your hot melt hose needs to be replaced.

Addressing these issues will help optimize your production process.

Why replacements are necessary

When everything appears to be working properly, the last thing on your mind is spending money to fix something that is not broken. Bypassing preventative replacement of hot melt hoses can lead to more significant issues down the road.

- Hot melt hoses fill up with char over time, compromising the effectiveness of your equipment

- Large amounts of char buildup can restrict the amount of glue released to the product, leading to pop opens

- Clogged nozzles and modules lead to unexpected downtime, causing more harm in the long run

- Exposed electrical wires and wrapping compromise the integrity of the hose and cause safety concerns

- Over time, the hose provides less flow, even when all filters have been replaced

To avoid potential dangers and ensure your production is running at peak efficiency, it is essential that hot melt hoses are replaced, whether there are visible issues or not.

With these best practices and tips from our team of experts at Chicago Glue & Machine, your hot melt hose will be in good hands! Don’t hesitate to contact us for more information on hot melt hoses or with any questions, we’re available 24/7/365 to help keep your production line up and running.