How Dyne Levels Are Used for Troubleshooting Adhesive Applications

Dyne levels are often used for packaging applications to determine whether or not the coated or uncoated boxes, trays, or cartons can be bonded by hot melts typically used for packaging. It can also be used to determine if the material you’re using is the cause for applications not properly adhering.

Dyne Levels and What They Mean

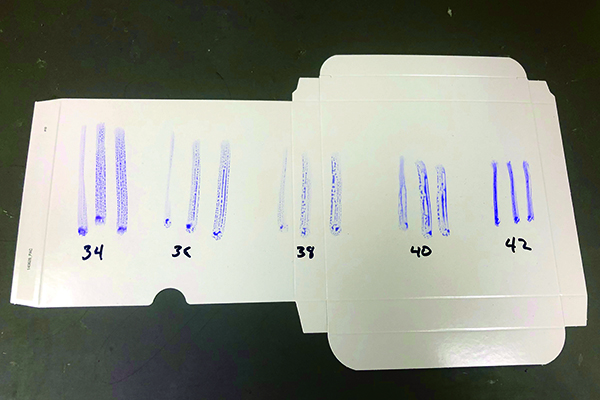

The surface energy of a material is measured in dynes. Therefore, dyne markers measure the surface energy of the materials they are applied to. Here are what each of the dyne level readings mean:

– If the dyne level of the material being bonded is 40 or higher, it means a standard packaging adhesive can be used.

– If the dyne level of the material being bonded is between 38 and 40, it becomes more difficult to use a standard packaging hot melt. However, it is still possible with specialty packaging adhesives.

– If the dyne level of the material being bonded is below 36, it is most likely not possible to adhere the material with a packaging hot melt adhesive. In this case, either a new material or a new adhesive needs to be used.

Troubleshooting with Dyne

With more and more recycled board stocks being used, the dyne levels are reading lower and presenting more of a challenge for packagers to use their typical hot melt adhesives. In many instances we find that our customers don’t even know that they received a different board stock from their supplier. They suddenly find that their glue stops performing, and they call us for troubleshooting. When we use the dyne level markers, it reveals that it is a new, recyclable material and therefore a new adhesive application needs to be used.

If you find that your stock isn’t sticking like it used to, call Chicago Glue. We can use the dyne level to determine if your material needs a new adhesive.