How the Graco InvisiPac Hot Melt System Can Help You Go Green

It’s no secret that all types of companies, including manufacturers, are looking for ways to make a positive impact on the environment through their operations. As companies increasingly prioritize sustainable initiatives, adhesive applications may be overlooked. So, if you’re brainstorming ways to implement eco-friendly practices in your manufacturing processes, we can help! With the Graco InvisiPac Hot Melt System you can improve production efficiency, stabilize your glue consumption rates, and go green! Here’s how:

Save Energy & Reduce Your Carbon Footprint

The InvisiPac’s tank-free system allows it to heat up in less than 10 minutes, resulting in a 48% reduction in start-up energy. It even has an auto shut off after 1 hour of idle time, resulting in 26% less use of idle-time energy.

The bottom line? With the InvisiPac you’ll be consuming less energy, thus reducing your carbon footprint! Not only that, but you’ll gain an additional 25 minutes of production time each time you turn on the machine as a result of not waiting for it to start up.

Use Less Materials & Generate Less Waste

When you install an InvisiPac in your plant, you’ll use less materials overall – the main one being glue! Because hot melt adhesives are oil-based, non-recyclable, and require 24 gallons of water per pound to manufacture, they aren’t known to be environmentally friendly. But with the InvisiPac you can reduce adhesive usage between 20% and 40%+ depending on your application – thus reducing the hot melt’s impact on the environment.

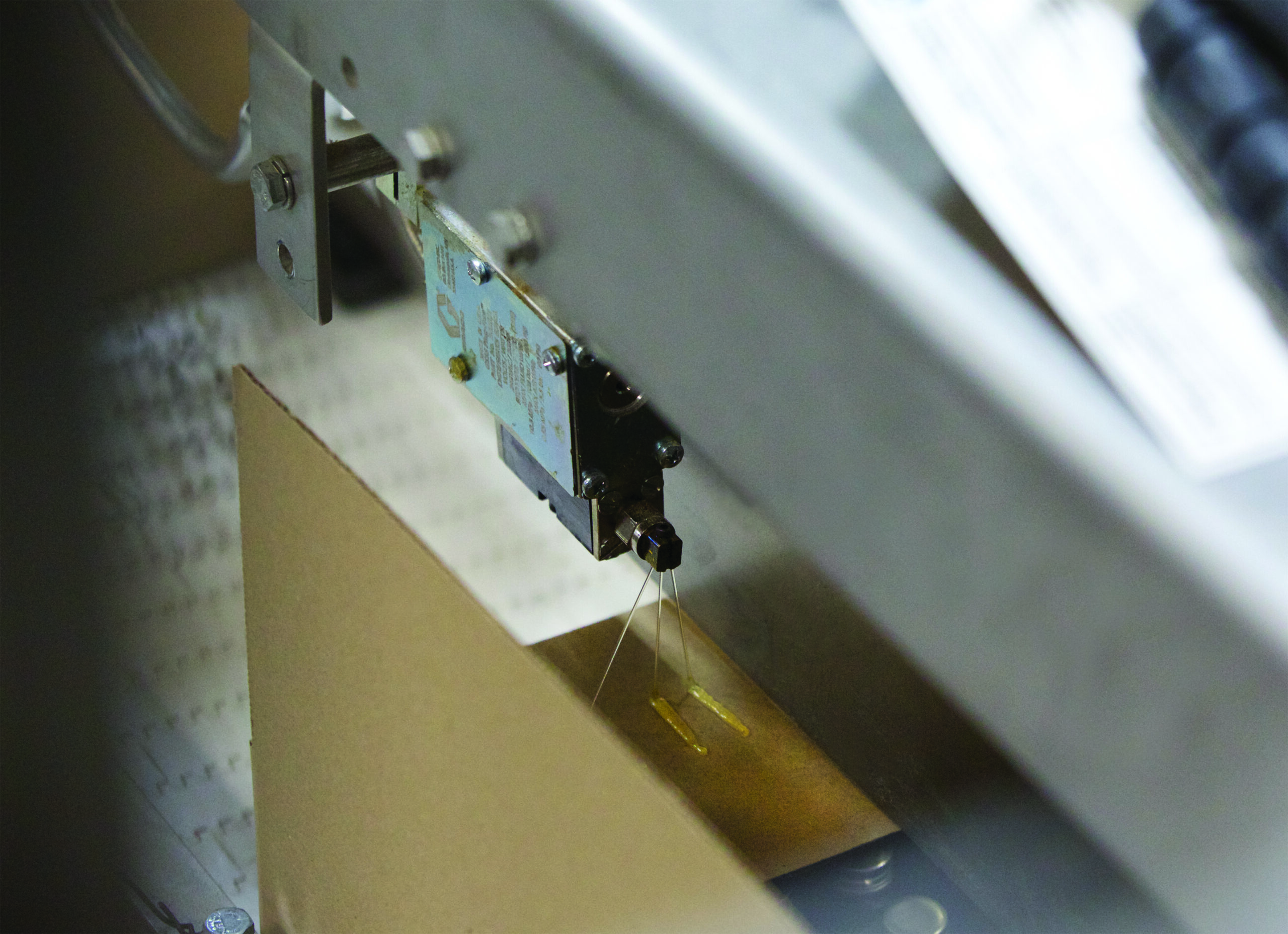

How? The InvisiPac’s tank-free system will keep your hot melt at a consistent viscosity and dispense it using the right amount of pressure. On the other hand, a typical tank system would have varying high and low levels of viscosity as the operator adds more cold adhesive to the equipment. The control that the InvisiPac has over the adhesive viscosity and output pressure results in more accurate usage and less unnecessary overage.

You’ll also experience less damage overtime to your packaging system and spare parts. Because of the InvisiPac’s preciseness, you’ll have less waste in the form of boxes and labels that need to be repacked or resealed. And, due to the InvisiPac’s efficiency, the system and spare parts will last longer!

– The pump’s lifetime is over 10 years.

– The solenoid lasts 5 times longer than the leading competitor.

– Manifold and module filters eliminate nozzle plugs, thus requiring less frequent replacement.

Going Green Saves You Money

Reducing energy and material consumption is of course great for the environment, and it’s also great for your wallet! Less waste means less expenses. And more efficient equipment means less downtime and more productivity in your plant. The InvisiPac will even track your glue usage to help you determine the right amount to order. To see how the InvisiPac benefitted one of our customers, click here to read a case study.

What’s Next?

If your company is prioritizing sustainability this year and beyond, we’d like to talk more about the Graco InvisiPac Hot Melt System and its benefits. Our team would be glad to demo the system in your facility or virtually via a video call. Please contact us today to get a conversation started!